In the world of architectural and municipal design, lighting is more than just a utility—it is an art form that defines a city’s nighttime identity. Whether you are illuminating a sports center, a historical bridge, or a modern commercial facade, choosing the right LED fixtures is critical for both aesthetics and durability. At KUPU, we have spent over 16 years perfecting the science of outdoor illumination. In this guide, we’ll break down the five most critical factors to consider when selecting LED solutions for large-scale projects.

1. Precision Beam Angles for Architectural Detail

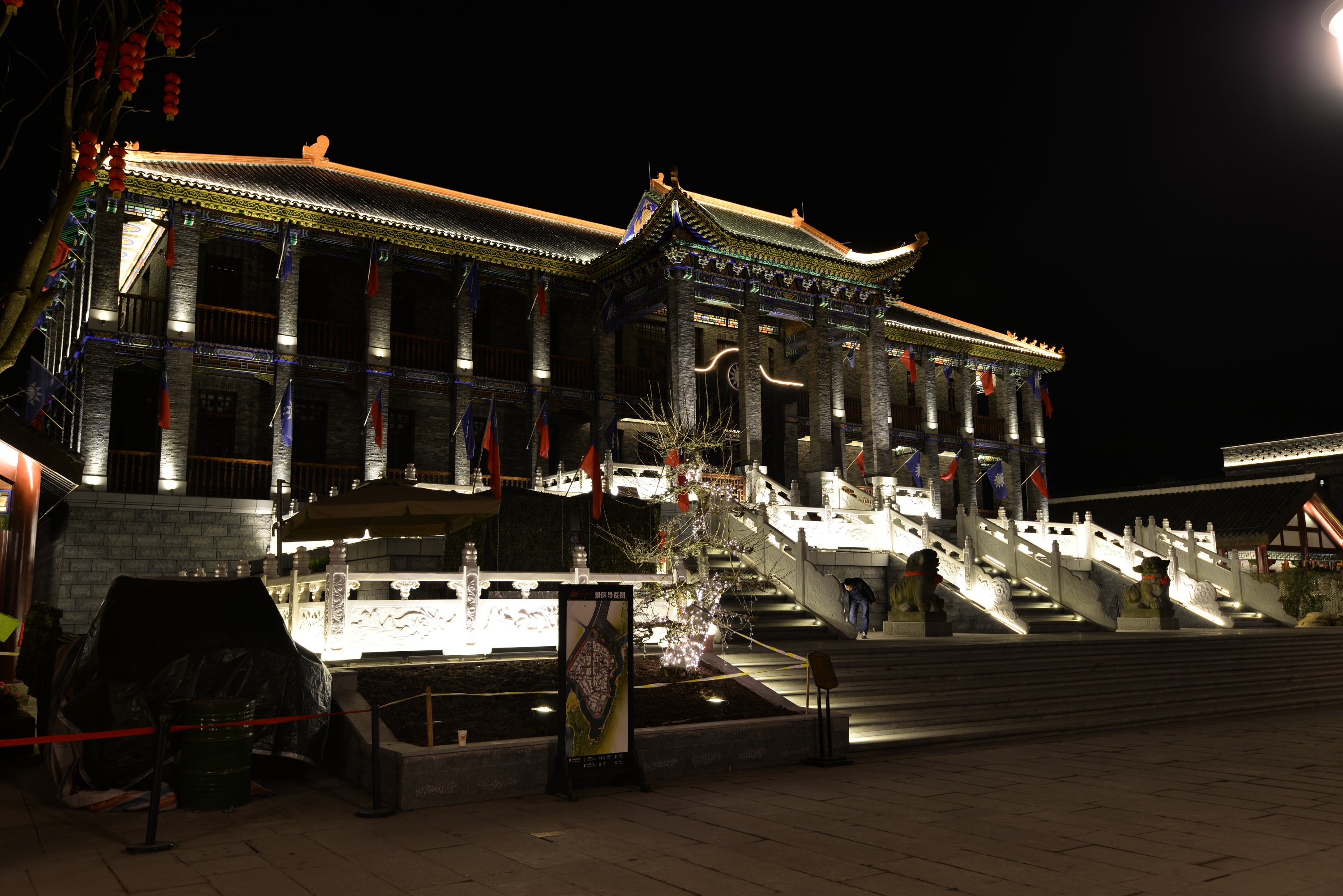

Not all floodlights are created equal. For architectural "wall washing," the precision of the beam angle determines whether a building looks elegantly textured or washed out.

Narrow Beams: Ideal for highlighting columns or tall vertical structures.

Wide Beams: Best for uniform coverage on flat facades.

KUPU Tip: Look for manufacturers that offer customized light distribution testing to ensure your project hits the exact parameters required by the design.

2. Durability: Navigating IP Ratings and Material Quality

Outdoor lighting faces the harshest environments—from scorching heat to freezing rain.

IP65 vs. IP66/67: For bridge and water-adjacent projects, an IP66 or IP67 rating is non-negotiable to prevent moisture ingress.

Heat Dissipation: High-wattage LEDs (like our 48W floodlights) require advanced housing designs to dissipate heat, ensuring the 50,000+ hour lifespan you expect from a premium product.

3. Intelligent Control Systems (DMX512)Modern "Cultural Tourism" lighting often requires dynamic color changes and synchronization. This is where DMX512 control systems come in. When sourcing your lighting, ensure the fixtures are compatible with smart controllers that allow for scheduled scenes, interactive water effects, and energy-saving modes during off-peak hours.

4. The Importance of Certifications (CE/RoHS/ISO)

For B2B buyers and government contractors, compliance is the first gate of entry. Always partner with an OEM/ODM manufacturer that holds ISO9001 certification. Products should carry CE and RoHS marks to ensure they meet international safety and environmental standards, reducing the risk of project delays or legal liabilities.

5. Customization (OEM/ODM) Capabilities

Every landmark is unique. Sometimes a standard catalog item won't fit the structural constraints of an ancient building or a uniquely shaped stadium. Working with a factory that offers customized design and prototype making allows you to tailor the wattage, color temperature (CRI), and mounting brackets to the specific needs of the site.

Conclusion

Success in outdoor lighting projects comes down to the balance of high-quality hardware and expert technical support. At KUPU (kupuled.com), we leverage 16 years of experience and a production capacity of 5 million+ sets to bring your vision to light.

Are you planning a lighting project for 2025? [Contact our engineering team today at Email: sama@kupuled.com] for a free consultation and quotation.